Turbosmart GenV Twin Port Internal Wastegate Actuator to suit Borg Warner EFR Series Turbochargers. This IWG actuator, has it all, taking technology from the Award-winning GenV range of External Wastegates, and providing unparalleled actuator performance.

Turbosmart GenV IWG (Internal Wastegate Actuator) Range provides improvements in boost control over your factory actuator. Our unique diaphragm system's large working surface area ensures increased boost response and control, at any performance or boost level.

Using Turbosmart’s locking collar system, you can also quickly change your base spring selection from 5, all the way up to 26psi. The Nitronic guide and Hard Chromed Intermediate Rod, mated with the swivel joint system, ensure the best possible lower chamber seal for true twin port control strategies and unequalled actuation range and control.

Available in

GenV Twin Port (Standard Cap): TS-0620-4012

GenV Twin Port (Position Sensor Cap): TS-0620-4014

Features

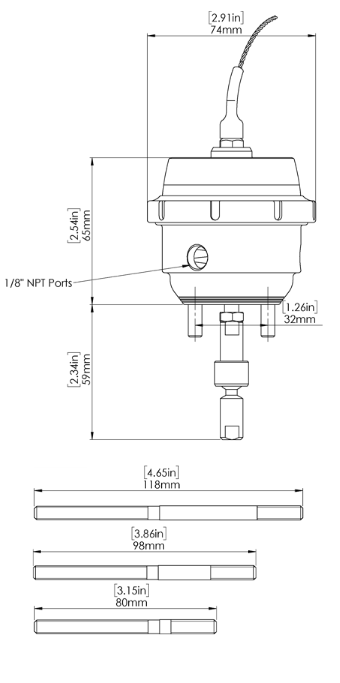

GenV cap including 1/8NPT reference ports

True Twin Port Control for a wide boost control window

Hard chromed Intermediate rod and nitride guide for cycle tested and proven reliability

Proprietary Swivel Joint for complete linear actuation

3 Secondary rods are included to ensure fitment to all B1 & B2 single and twin-scroll EFRs.

This is a bolt-on fitment for the Borg Warner EFR Series turbocharger, including Single and Twin Scroll B1 & B2 Turbochargers. Accessories are supplied to adapt to all variants, including all spring options.

SUPPLIED WITH

Turbosmart GenV Internal Wastegate Actuator

3 x Rods to suit BorgWarner EFR series turbos

3 x Springs: 5psi inner, 7psi middle, 14psi outer (pre-installed)

2 x 1/8 NPT nipples

4 x 1/8 NPT blanking plugs (1x pre-installed)

Turbosmart GenV HE Sensor

C Spanner / IWG Actuator Collar Tool

Turbosmart Decal

What is in the box?

You have everything to get up and going with a Borg Warner EFR Turbocharger. Our swivel adaptor allows the fitment of any rod you need quickly and easily, and we took this opportunity to put all the parts for all the current EFR ranges in one box. All 3-rod options, and every spring you could need are inside the box, ready for you to set up, on your EFR.

Is this a universal product?

No, this part number is specifically put together to suit EFR Turbochargers…. However, those handy people will quickly realise a lot in this box can be customised. You have a few rod options and all the springs. If you have a small bar bender and consider yourself capable, you’d be surprised what you could come up with.

What do I need a sensor cap for?

Not everyone will - But for those interested, or pushing the absolute limits… We’ve found that having a wastage position sensor is important to the data log. We’ve even worked with some engine calibrators on using that sensor for closed loop, highly technical boost control strategies. More data is always better.

What spring options does the Gen-V IWG have?

You effectively have 7 options: 5psi, 7psi, 12psi, 19psi, 14psi, 21psi and 26psi with the use and combination of just 3 springs. And remember, this is just base mechanical spring pressure. Higher boost levels can be achieved with some boost control or reference manipulation.

What is Twin Port, and why would I need it?

Twin Port boost control allows pressure manipulation on both sides of the actuator's diaphragm. In the simplest of terms, this means you can have a much broader range of boost control options and often able to fit a much softer spring while still able to run very high levels of boost. This is because you can force pressure into the top cap, keeping the gate shut for longer.

TROUBLESHOOTING

Wastegate not actuating - Confirm signal hose is plumbed to a pressure-only source. Confirm preload during installation.

Poor wastegate actuation - Ensure the signal hose is not shared and is sourced as close to the compressor as possible. Check the seal on the fittings.

Poor wastegate actuation – Confirm no obstructions in the actuator rod path.

Boost creeping at high rpm - Wastegate flow path is poor, wastegate is too small for the application, ensure balljoint is not seized.

Failing the above, submit a technical request to Turbosmart with information on your engine configuration and photos of the installation.